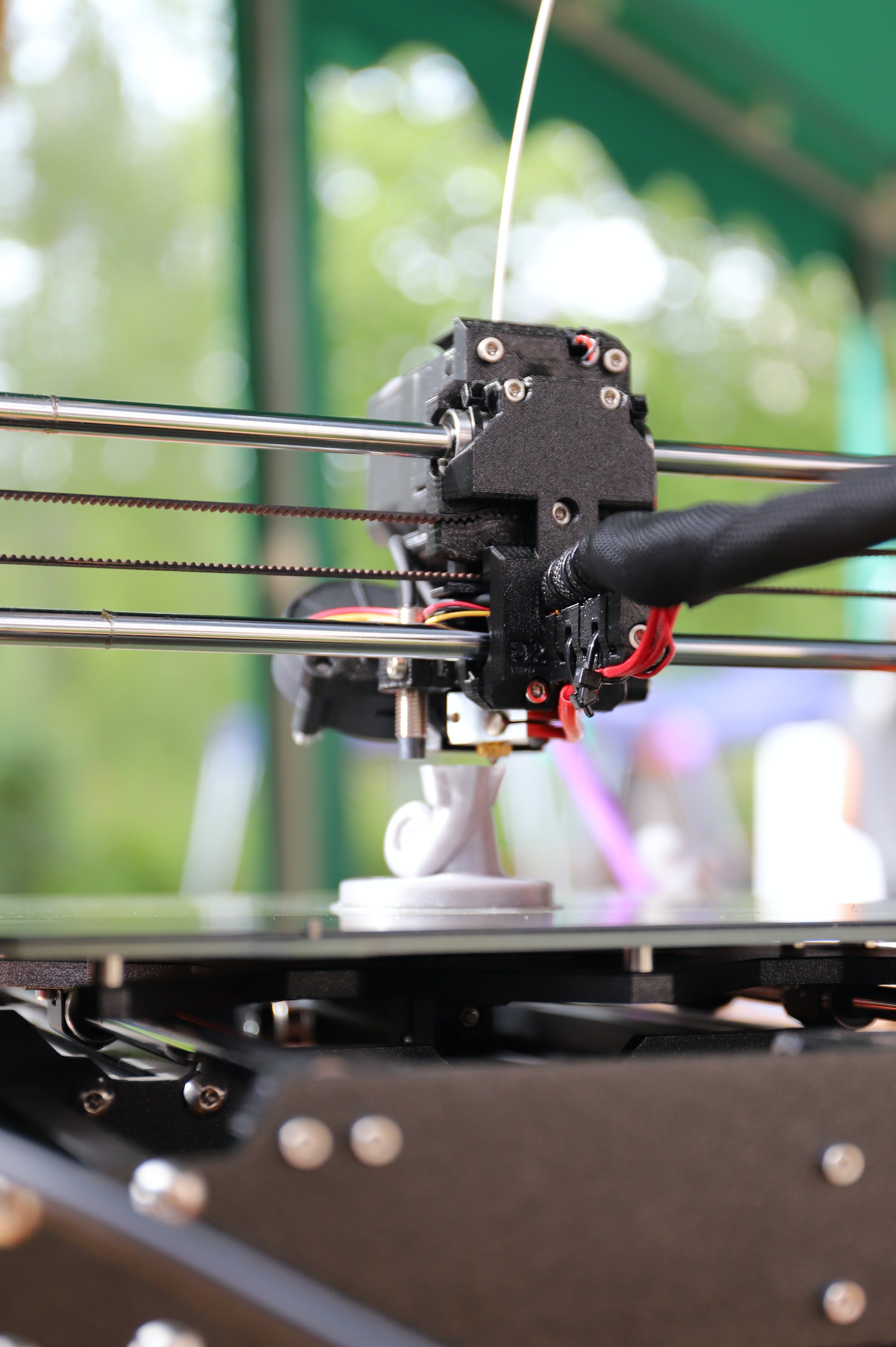

G-code, is a language used to control and communicate instructions to computer numerical control (CNC) machines and 3D printers. It consists of a series of commands and parameters that tell the machine how to move, position, and control various components like motors, heaters, and extruders. In the context of 3D printing, G-code is used to instruct the 3D printer on how to build an object layer by layer.

G-code is a plain text file that typically contains commands that are either standardized across many CNC and 3D printing machines or specific to a particular machine. Common G-code commands include:

Movement Commands (e.g., XYZ):

- G0/G1: Rapid positioning or controlled motion in a straight line.

- G2/G3: Circular or arc motion.

- G28: Home or reference the machine to a specific position.

- G90: Set to absolute positioning mode.

- G91: Set to relative positioning mode.

Extrusion and Filament Commands:

- M104: Set the extruder nozzle temperature.

- M106/M107: Control the cooling fan.

- M109: Wait for the extruder nozzle to reach a specified temperature.

Bed Leveling and Calibration Commands:

- G29: Auto bed leveling and probing.

- G30: Single-point bed probing.

Tool Change Commands:

- T0, T1, etc.: Select a specific tool or extruder head in multi-extruder printers.

Pause and Resume Commands:

- M0, M1: Pause the print for user interaction.

- M226: Pause for a filament change.

- M24: Resume a print.

Comments and Annotations:

- Comments in G-code files are preceded by a semicolon (;) and are used to provide information to humans reading the code.

The G-code is generated by slicing software during the slicing process, where it interprets your 3D model and your print settings to create the specific instructions for your 3D printer. Each line in the G-code file represents a command that tells the 3D printer how to move the print head, heat the extruder, control fans, and perform other tasks necessary to build your object.

Understanding and editing G-code can be essential for advanced users or for troubleshooting 3D printing issues, but most users rely on slicing software to generate the G-code automatically, ensuring precise and accurate 3D prints.